PureSip: Mechanical Engineering Senior Design Project

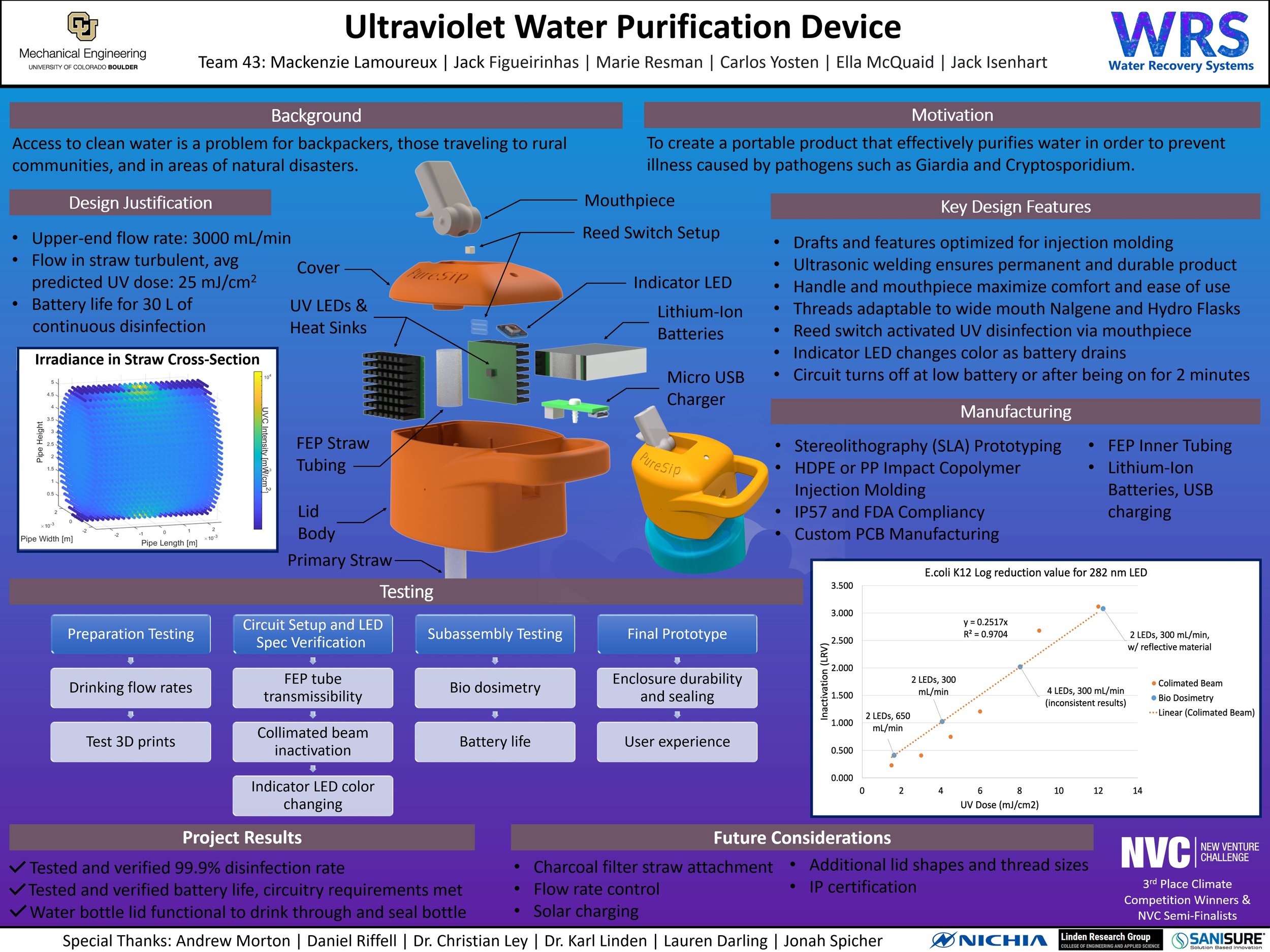

Throughout both semesters of my Senior year in Mechanical Engineering at CU Boulder, I worked with a team of 6 to come up with and design a product of our own imagination and form a tradeshow-ready prototype. While most of the Mechancial Engineering students went into the “industry Section” of ME Senior Design Projects and worked with a client such as Boeing or NASA to create a engineering design based on their specific needs, I was a part of the “Engineering for Social Innovation (ESI)” section. This meant that the we would have to come up with our own product and design it for ourselves, and at the same time conduct market research for our product and justify its viability as a business if it were to be manufactured at scale as a consumer product. Our product was PureSip, the lid that fits onto your waterbottle, and purifies the water as you drink.

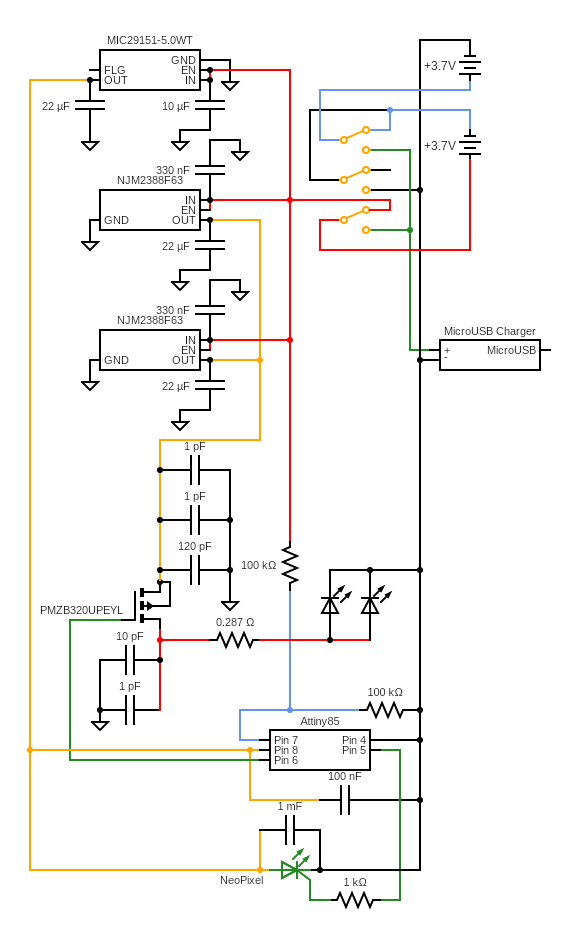

My role in the project started as being named the Logistics Manager. This was an important role during the developement of our idea and initial contacting of outside sources. I was responsible for taking all meeting minutes for our team meetings and assigning specific action items and deadlines to my team members while we were fleshing out the initial design interations. I was also in charge of all external email contact with resources such as our director, UV LED manufacturers, UV Purification research labs, and more. I was also responsible for many technical aspects of the project. I was able to research the testing process for UV Purification devices to find the right UV light wavelength to use for the most effective purification, as well as find manufacturers that made LEDs that would effectively provide that wavelength to the water with an effective amount of light intensity. Once the UV LEDs were selected, I singlehandedly designed all of the circuitry for our product, choosing the batteries, voltage regulators, microcontrollers, switches, RGB LEDs, and all other necessary components and combining them into a testable circuit that my teammate would be able to manufacture into a miniturized circuit board to fit in the cap. I also played a significant role in the entrepreneurship side of our project. A detailed explanation of the circuitry is here. As part of the ESI Senior Design Project Section, we had to not only design a working product, but develop a business plan for producing it as a consumer product and pitch it to the Get Seed Funding team, and to real investors and venture capitalists in the CU Boulder New Venture Challenge (NVC) competition, where dozens of teams compete for $100,000 of funding for their business ideas. I was one of the presenters of our pitch deck to these judges and we are proud to have won $500 in funding from the Get Seed Funding group, finish 3rd at the NVC Climate Night competition, winning $1,000 more, and making it to the Semi-Finals of NVC.

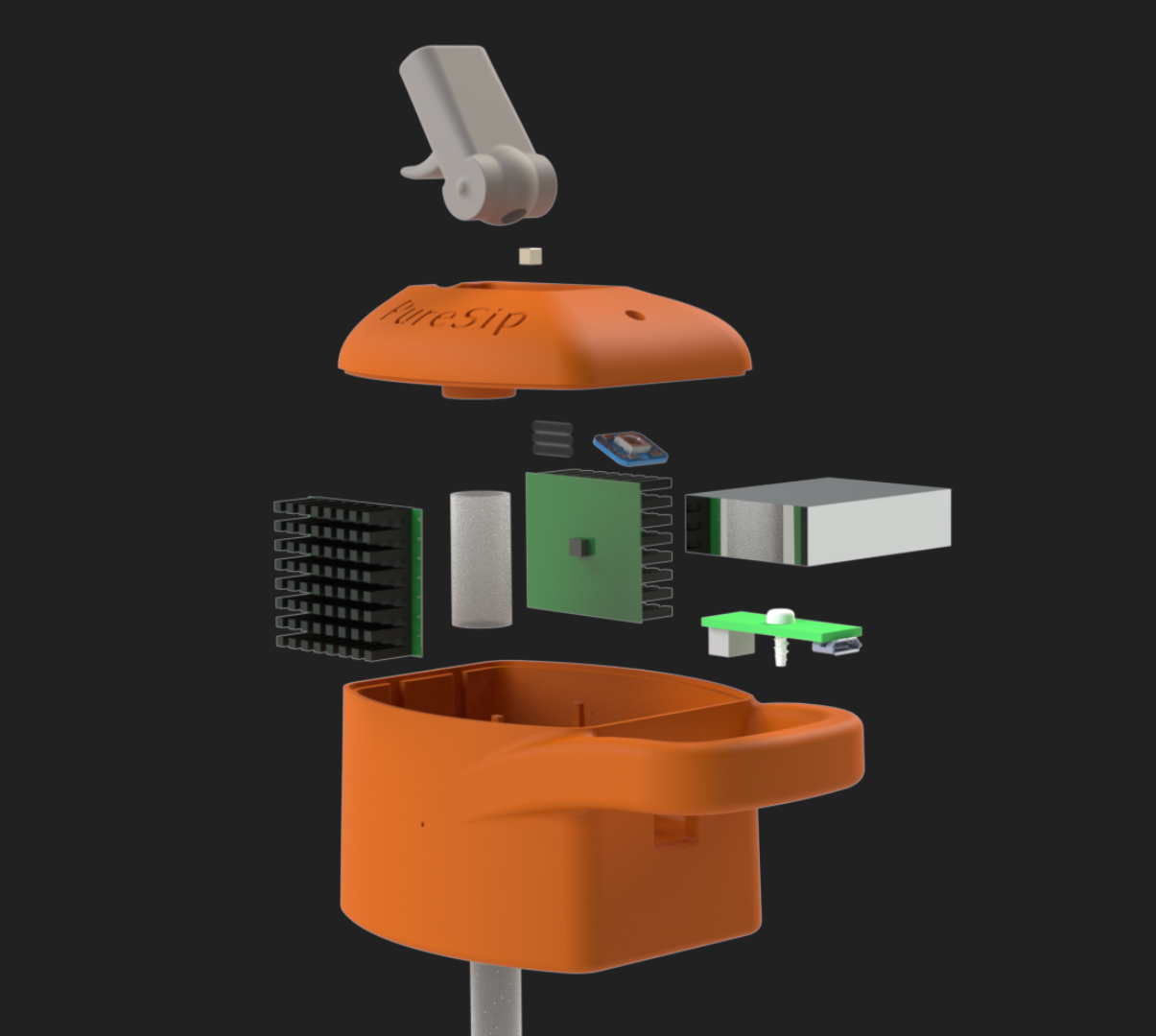

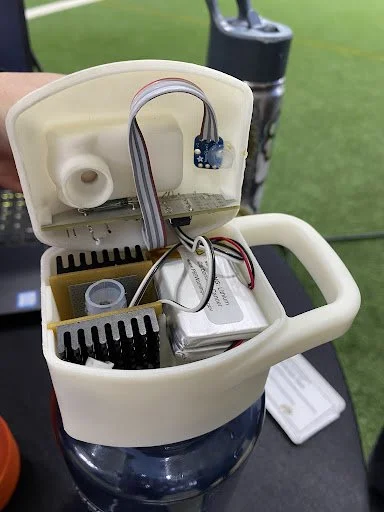

Our project was not obvious at first, and only after many months of design changes and prototyping were we able to come up with a design that we were proud of. PureSip uses a combiniation of UV Purification and Charcoal Filtration to clean out sentiment and kill bacteria in the water you fill your waterbottle with. A charcoal filter at the bottom of the straw stops any sentiment from entering the users mouth, as well as improves the taste of the water before it passes through a section of straw inside the lid that has two UV LEDs pointing inwards towards the water and shines a wavelength of light (282 nm) that is proven to destroy the DNA molecules of harmful bacteria such as E. Coli, Giardia, Cryptosporidium, and others known to be common causes for gastrointestinal issues. The design is as fool-proof. The purificiation is switched on when the user flips up the mouth piece and an RGB LED displays to the user how much battery is left in the product by switching from Green to Yellow to Red to Off with battery life. The battery life is long enough that it will last the user long enough to take on a week long backpacking trip if they drink at the typical rates needed for athletic activity, and it is rechargeable with a common microUSB port. Due to the amount of electronics incorporated in our design it is also waterproof to ensure that it will survive in outdoors conditions and is protected when the bottle is being filled or cleaned.

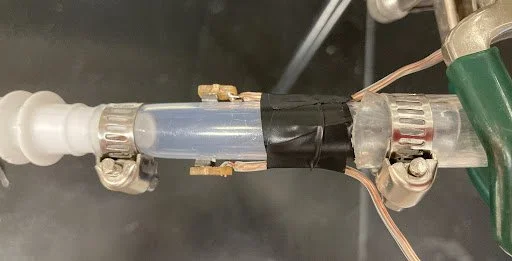

In order to be sure the UV Purification was effective enough to kill the waterbourne pathogens, we were able to utilize the Linden Research Lab and at CU Boulder which specializes in UV water purification devices with the help if some willing and interested researchers. In order to achieve the 99.9% disinfection of bacteria required to be FDA complient as a purification device, we found that 2 UV LEDs shining 282 nm light were required to purify water flowing through the straw at 300 mL/min which we would restrict the flow to. 300 mL/min is a comfortable drinking rate and is much better than that of similar purification products such as the LifeStraw which has a painful drinking rate of about 160 mL/min.